How COVID-19 Is Changing Nufarm’s Approach to the Ag Business

CropLife® interviewed Brendan Deck, General Manager of Nufarm North America, on March 31. Deck shared insight on managing a crop input business during the COVID-19 pandemic, including how the company is being affected from the standpoint of its U.S. workforce all the way through to its operations in China. He also opened up about how the pandemic is shaping the future of agriculture. Deck, a New Zealand native, has for the past five years lived in Chicago, where Nufarm operates two plants that are central to its U.S. business.

Brendan Deck

What are your priorities right now in how you go about managing your business?

If you look back two to three weeks, the conversations we were having were very different. In fact, I was reading (Nufarm’s) March report for the North America region at this time last year. We always open our report with a safety update, and the issue of the day – and I don’t want to take this lightly – was that one of our workers had a blister on his thumb for touching something that was too cold in the workplace, and we needed to talk about the safety of wearing gloves in cold environments. I look forward to what my report is going to be for March 2020, and I wish I was talking about a person with a blister on his thumb.

It is a dramatic change. In considering how we operate in this environment I start with the absolute first and foremost issue: Safety comes first. Fortunately, as a company, we’ve been driving what I call a safety culture as our number-one priority for the last five years. I think about safety going back five years, and we used to talk a lot a lot about wearing a safety vest or hardhat at the plants. Whereas in today’s environment, and over the last few years, the safety message has gone a lot wider across our business. For example, as we drive a car to visit customers daily, we have messaging around not using mobile phones. It’s not been a sudden a change in the way we talk but a reinforcement that safety comes first, and the health and wellbeing of our people is number-one priority in everything we’re doing.

We’ve put in place response teams. These are groups who are charged with understanding and finding information and discussing what’s needed of customers and taking all aspects of the business and being able to bring that together. Communication at this time becomes absolute king. When you’re in a crisis situation like this, communication is absolutely paramount. We have to have total trust in our people. In our business, you hear me say a lot that our people are our greatest asset. There are probably some simple rules we’re trying to follow that maybe we followed in the past on a monthly or quarterly basis. Today, it’s almost daily. You’ve got to have plans, take action, and you’ve got to be a doer. Then you review and adjust. You can’t have people in meetings all day long — you’ve got to allow people to be doers. Then we get to take time to review and adjust and then you continuously repeat that cycle. In a way, it’s consolidating the business into a daily cycle as opposed to a monthly cycle we had in the past with how COVID-19 is changing our environment.

Can you offer other specifics on how your sites are addressing safety during this pandemic?

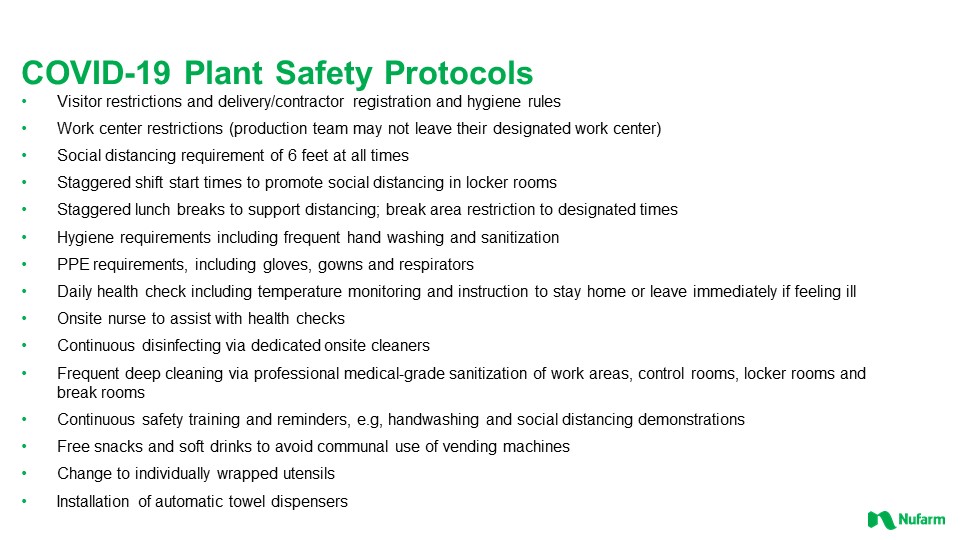

We’ve got nurses at our site in Chicago Heights checking the health of people as they come to work for every shift, and that’s about giving piece of mind. The messaging around social distancing is something you’ve got to continue to sell. There’s also a part that says, if you are not feeling well, please do not come to work and the responsibility of that. There are people that want to come work, because they want to earn money and put food on the table. There are other people that want to come to work to see products delivered to meet farmers’ needs. We’ve got to make sure that for whatever reason everybody’s there, they are coming to work healthy.

Regular cleaning at the sites, rotating staff, small groups are other (measures we’ve taken). Our teams are used to having their lunch break with groups of 20, 30, 40 people. Lunch breaks now are no more than groups of two or three. I mean, humans are social characters – they want to interact, so how do we allow that interaction to happen but give the space that is required. (Editor’s note: See Nufarm’s COVID-19 plant safety protocols at the end of this article.)

Have Nufarm’s operations been affected in terms of shutdowns?

Not at this stage. Look, it’s a daily discussion. We are very fortunate that the three plants that we’ve got running and our logistics centers are running at near full capacity. We’re taking more time on cleaning process; we’ve got smaller groups operating so the social distancing is adhered to. We’re rotating key staff on a faster basis so we don’t have staff in the same spot at same time. Some of those (measures) slow you down slightly, maybe in some of the efficiencies you’d like to see. But overall, our plants have been running at almost full capacity, and for our delivery and logistics operations, we’ve been able to deliver everything we’ve been producing. I’m saying that as I’m sitting here on the 31st of March; tomorrow morning we’ll have to start again.

We’re trying to make sure we’re keeping everything running and fortunately by having three plants, we can move product around, which means we also have multiple logistics opportunities to ship product. At this stage we’ve been fortunate that Nufarm has been able to continue to produce and deliver product that our customers are asking for. I feel very lucky to be in agriculture.

Tell us more about your plants – how reliant are they on China for raw materials and intermediates?

We have two plants in the Chicago area: an insecticide/fungicide seed treatment plant in Alsip, we have a main herbicide plant in Chicago Heights, and a second herbicide plant in Greenville, MS. Around ingredients and raw materials, we do have a lot of raw material supply coming from China. Some comes from Europe, and we also have plants in Australia. Our primary source of raw material is China. We have, at this stage, not seen any issues with shipments out of China. It’s looking like China is back in action following the new year break, which turned into an extended break. We were fortunate with inventory we had on hand.

We have two plants in the Chicago area: an insecticide/fungicide seed treatment plant in Alsip, we have a main herbicide plant in Chicago Heights, and a second herbicide plant in Greenville, MS. Around ingredients and raw materials, we do have a lot of raw material supply coming from China. Some comes from Europe, and we also have plants in Australia. Our primary source of raw material is China. We have, at this stage, not seen any issues with shipments out of China. It’s looking like China is back in action following the new year break, which turned into an extended break. We were fortunate with inventory we had on hand.

As you know, we had a tough season here in North America, and that is not good for business – but what it’s been good for in today’s situation, is that we had more inventory than we would have liked in a normal business cycle. The supply chain team did fantastic job (laughs), because it’s enabled us to see any shortfalls out of China and we’ve been able to handle it. We are in a good situation with raw materials arriving into the country in a timely manner.

My message to our customers and farmers out there is there is a supply line and it is in operation, and we are getting good supply out of China at this time.

But there was an interruption?

There was an interruption. They had the Chinese new year, where everything shuts down for a two-week period. It really ended up being a four-week period. We were probably very fortunate that we had a tougher season because of the wet spring last year that there was some excess inventory here in North America.

What are your lead times like?

We would never have enough to see a complete season through this. We are manufacturing and importing daily and weekly. Our response team is looking for what-if scenarios. We need supply lines to remain open. We need logistics and delivery systems to remain open to enable us to continue to deliver product. We’re not sitting here with a full season’s inventory of finished goods. We would see disruption in the supply line if we got further delays on a number of fronts. If it’s from supply out of China, can we look to our other locations around the world – Europe or Australia, for example, to get product? If we had an interruption at our plant in Chicago, are we able to produce product in Greenville? Are we able to move product between the plants?

On logistics, if we have an issue with a warehouse in a certain area, are we able to pull product from other warehouses? So, there are a lot of contingency plans and what-if scenarios being reviewed on a daily basis. We have a lot of options available to us. If we did get a slowdown on any one of those areas, we believe there are opportunities for us to work around. If there was a slowdown on one particular main area for a long period of time, that would clearly have impact on the business.

Has Nufarm looked to other risk mitigation measures such as backward integration and alternative sources to reduce reliance on China?

Sure, and it goes deeper than that. The plant in Greenville is new – we just invested $30 million into that plant in the last six months. It only opened in October 2019. The reason we did that in Mississippi was for that exact reason, so that we don’t have all our manufacturing in one location.

When we thought about how our business is growing and expanding, that meant our production capacity was getting stretched. One of the options was to increase our plant size in Chicago – we’ve got the land and availability to do that. In the end, we decided to look at a location that, for start, was closer to our Southern customer group. The Southern U.S. is a big marketplace for us. It also gave us options to think about the what-ifs of having everything in one location. We weren’t sitting there thinking about anything like COVID-19 being the reason we would have a plant in Mississippi, but it clearly has now given us some good options for supply. There’s one example of what we’ve looked at as far as having a footprint here in North America to give us options.

When we thought about how our business is growing and expanding, that meant our production capacity was getting stretched. One of the options was to increase our plant size in Chicago – we’ve got the land and availability to do that. In the end, we decided to look at a location that, for start, was closer to our Southern customer group. The Southern U.S. is a big marketplace for us. It also gave us options to think about the what-ifs of having everything in one location. We weren’t sitting there thinking about anything like COVID-19 being the reason we would have a plant in Mississippi, but it clearly has now given us some good options for supply. There’s one example of what we’ve looked at as far as having a footprint here in North America to give us options.

From a Nufarm perspective on a global basis, clearly having plants that have central locations is another point. We can draw from Australia; we can draw from Europe. It gives us another option to review on our supply side.

Are we going to remain reliant on China? The answer is yes, there still will be heavy reliance on China. There are clearly other options that we are investigating now. India is one. This is a worldwide crisis, but we will continue to look at India, Indonesia, and other locations around the world where we could source our raw materials or additives and ensure we have continuation of supply as we move forward.

Are there certain materials you’re looking to procure elsewhere?

For Nufarm, our number-one molecule is 2,4-D. What we have done over the last couple of years, there are obviously sources out of China, but we’ve also got a synthesis plant in Australia and in the UK. That’s been a very key part of our strategy is making sure we’ve got multiple locations to be able to actively source 2,4-D and synthesize. One thing is to be able to get a raw material, the other is to be able to produce the product, and synthesis is a big part of that.

What is your take on how the retailers are impacted? They are concerned about ensuring that product gets where it needs to be.

All of our issues are passed on down the chain, whether it’s from a manufacturer, to a warehouse, to a distributor, to a farmer. What we’ve got to realize is that any impact on my end is going to have an impact on many people down the chain. This has shown how relationships come into play. How good is our communication, and how transparent is our communication? I think that comes down to partnerships and trust. My communication with our key customers is absolutely vital at this time. They need to be able to trust that I am going to be communicating the facts so that we can do things together. A lot of this is about what we are doing to ensure the industry of agriculture is staying afloat and that the season here in 2020 is going to see food on our tables come ‘21, ‘22. We need to work together.

If we get under pressure and stressed with what’s going on and we fail to communicate to our partners, that’s when we start to see cracks appear and issues become bigger. Now, how do we manage that? I think a lot of it comes from experience. You look at what we’ve just been though over the last 12 months. There was a lot of discussion going on in the marketplace around tariffs: are we going to have tariffs; what’s going to be the duty; what are the trade wars going to be mean. A lot of people change some of their buying decisions based on (uncertainty) around tariffs. That has caused some issues. A lot of this has centered around key management. You’ve got to take stock; you’ve got to look back a little bit. I always say future is in the headlights, but there are times when you do look back.

We have had situations – not like COVID-19 – but we have had supply issues. How do we make sure we’re not creating panic buying, or we aren’t creating excess inventory in one part of the country where it could be utilized in other parts? I’ll tell you, the key to that is communication and trusting in one another. Industry in general has learned a lot over many years that this is a time when we talk to one another, whether it’s manufacturer to manufacturer or retailer to retailer. There is communication going on, because at the end of day we’re all in this to try to ensure that the end user – the grower – has the right products at the right time to enable their operations to keep going.

There may be some compromise with what I’m doing with one customer, in the sense that if it’s better for another manufacturer to supply the customer because it may be logistically more sensible, then maybe we have that discussion. The most important part is communication, and the word trust – that we trust in one another’s communication.

We can only do what is physically available to us and we have to make sure people understand this. Don’t tell people I have 10 million gallons of product, or a million pounds of product available at all times, if I don’t. Let’s be clear on what is available, what inventory levels are in the country, what inventory levels are on the water, and what inventory we are still waiting to get from certain locations. Fortunately, some of our systems and the way we can communicate makes it easier, to share the information in a trusted and reliable way. It allows for some of those decisions to be made in a faster and more efficient way.

What are your customers saying – what are their concerns right now?

Customers are asking, quite honestly, some of the same questions you are. We’re good today, but what about tomorrow? This is where I have to say, our business is good today. We have a number of contingency plans in place and what-if scenarios, but this is a very fluid time. I have to be open, if something happens tomorrow that is outside my control, we may see disruption. We want our customers to hear that we are forming plans and we are doing our due diligence and reviewing and adjusting those plans as we need to on a daily basis.

It would be unwise of me to say that in two months, don’t worry about it, we’ll all be OK. We need to live in the real world, and that is we don’t know what tomorrow is going to bring. We need to adjust our plans and communicate our plans and our ability to deliver what the customer wants on a far more regular basis than what we’ve probably ever been used to.

How do you think the pandemic is going to change agriculture?

I think it’s going to make us as manufacturers, if I can start there, look at those questions of where we source our product, where is our footprint. Are they closer to our customer base? We are going to be making sure we’re looking at those sorts of questions, and how efficiently and effectively can we supply product to an end user from our locations.

We’ve just over the last few years put a team into China that’s our procurement team. We have a staff of just over 25 people based in China, so that we are far closer to our supplier and get a better understanding what’s going on there on a daily basis. I think it’s been an absolute winner for us right now, because the messaging I’m getting daily is from my people, and they are in touch with our suppliers in China, so that we’re getting what I would call factual information on a daily basis.

The sharing and understanding of where inventory levels are in the countries where we have product is important: we sold it to a retailer, has it gone to an end user, how do we discuss that so that we know where there are tight spots or surplus inventory at any one time. That is going to be key. Every business today is wanting to improve their forecasting and ability to plan. We are going to see businesses looking to have better communication, which leads to better planning and being able to communicate that back.

Our warehouses and distribution centers don’t have endless space. We don’t have enough to say, let’s just load up on inventory for six to eight months – we don’t have the working capital to do that. People’s working capital is going to become tighter because of this (crisis). Financial constraints are going to be even tougher going forward. We’re going to have to manage balance sheets with an even tighter rein than what we’ve been doing in the past, which means we need to have better communication between suppliers of raw materials, manufacturing, logistics, distribution, and the end user. That communication needs to become tighter.

If there’s anything we can learn of this situation, and we’re not anywhere near the end of it, so I’m sure I’m still going to learn a lot about it, is how do we bring that communication to being more trusting and reliable all the way through the supply chain from the manufacturer right through to the end user. If I don’t know what a farmer has in his or her barn, I’m not sure if that person is going to be buying the same amount this year as they did last year, or if they are planting the same acres or if they change their crops. All those decisions that are made at farm gate by the farmer impact our business. How fast can we hear that information so that we’re doing things to help the grower be more efficient, or are we catching up halfway through the season and then it’s too late. So, timeliness of communication and sharing of information is a learning experience from this.

Given that growers are still going to plant, and you still have inventory coming consistently from China, do you expect business will be relatively normal?

I’d love to think so, but there are so many variables. Our business is about people. People are worried. Today I had nearly 200 staff working in our plants. Their families are asking me questions: Is it safe to be at work? What are you doing to ensure my husband or my wife or my partner is not coming home with a virus? So, how do we make our teams feel that our number-one priority is safety and health and wellness. There is a mental part to all of that as well – mental wellbeing.

People are stressed. People are worried. To be honest, that’s what scares me most. I don’t know what’s going through some of the minds of the people who work for me. What are they being asked by their husbands, wives, and children? How can I make that person feel that what I’m doing is putting their safety at the forefront of every decision I make.

I worry about logistics, yes, and I worry about product arriving on time. But my biggest worry is how do I look after our people and make them feel that going to work in a critical industry to supply inputs to farmers so they can plant their seed and produce food, but at the same time do it safely – both mentally and physically. My teams that are running plants and operations, they have two jobs: one is because coming into spring it is the busiest time of year, and we need to get product delivered to farmers. That’s critical. They are also managing the wellbeing of our people, so that’s critical. We have people who are asked to do things they weren’t asked to do three weeks ago and they’re having to do it on top of their normal day job. There is a lot of stress and worry out there, and how we help people manage through that is probably as vital as managing the logistics or the import of raw material.

Is there anything you would you like to say in closing?

What we are doing today, and depending where this all goes, may be different than what we’re doing tomorrow. That is the challenge that we’re all learning is that this is a very fluid situation. I would be a poor leader of a company if I made guarantees. That would be unwise. My statement is that we will review, we will plan, and we will take actions on a daily basis as needed to ensure that we are delivering our products for as long as we can. What I hope happens is that this crisis lessens, and I can’t say it’s going to go away, but lessens to get back to a more normal work lifestyle, in which case we get back to full force. But if this continues to be around for long time, I’m going to have to adjust all the things that are in place today. It’s how fast you can do that and how proactively you can do that.

I am so proud of the team at Nufarm, because people have gone that extra mile, and they’ve gone that extra mile for the farmer, for the retailer, for the distributor, and for themselves. That is a true team environment. As much as you hate these situations, it does at times makes me feel good inside, that people are good. They do want to do what’s good for one another and they want to help one another. It’s a good thing to see. I think we need to pay a huge thank you to multiple people across the businesses and across the industry who are working tirelessly to ensure that product is delivered and farmers can do their jobs.