14 Fertilizer Blending Systems for 2019

Heavy duty. High capacity. Declining weight. High speed. Continuous flow. These are just some of the fancy terms used to describe the latest fertilizer blending systems on the market today. From Adams Fertilizer Equipment’s Direct Drive Blender Series, to Sackett-Waconia’s Bulk Fertilizer Terminals, ag retailers have a number of units available to them as they consider their fertilizer blending needs for 2019. View the slideshow above to get the latest rundown.

-

-

1 of 14

InterSystems Dry Fertilizer Blending System

GSI

GSI’s InterSystems engineered-to-order heavy-duty fertilizer equipment offers nearly double the speed of any other fertilizer blending tower on the market. It can fill 13 24-ton trucks with custom fertilizer batches in one hour and sustain that rate for a full day, providing shorter wait times. Product flows from the top of the tower to the truck in less than 5 minutes. Three hundred-ton-capacity stainless-steel bins can hold up to 14 different products. Two level sensors per bin ensure bins are continuously fed to keep product moving, without stopping to refill. Two 8-ton weigh hoppers have twice the weighing speed of competitor towers. -

2 of 14

Low Pro Minuteman

R&R Manufacturing

The 16-Ton Low Pro Minuteman has been designed with many of the same features as the Minuteman 2 blender — except it’s larger. The unit measures 10 feet in diameter to reduce height, has heavy-duty gear reducers direct-coupled to TEFC electric motors, and has larger augers than R&R’s standard units for improved In-Feed and Mix times. The blender still has low horsepower requirements even with the new bigger and faster features. -

3 of 14

Tower Blend System

AGI Yargus

The Tower Blender is designed for high-capacity retail or wholesale use, providing another efficient fertilizer handling option. The new six-legged design feature, with larger square footage, allows for more room for service and maintenance. The Tower features the reliable and proven Tapered Auger Vertical Blender, with the option of expanding capacity by adding a second blender. Also standard is up to 18 bins, a collection hopper, and up to four weigh hoppers. The Tower Blend System can?be custom-designed to fit blend and capacity requirements up to 300 tons per hour. The Tower is an all bolt together design with no field welding required. The tubular modular design with side cladding assures years of dependable use. -

4 of 14

Decline-N-Weight Blending System

Adams Fertilizer Equipment

Adams Decline-N-Weight Blending System offers both single- and multi-hopper designs, including standard, low-profile, and micronutrient hoppers for dry mixing combined with a state-of-the-art declining weight impregnation system. Adams Decline-N-Weight is operated by LEC’s PLC control system, making it the smartest Decline-N-Weight system in the industry. -

5 of 14

Precision Fertilizer Blending (PFB) Systems

Sackett-Waconia

PFB Towers feature the HIM mixer. Its superior design allows for efficient and rapid blending and equal distribution of advanced liquid and dry additives. PFB Technology uses NTEP-certified weigh systems and a garner-style design to provide high quality and high speed without sacrifices to either one. PFB Towers provide the capacity, flexibility, and reliability that dealers and their customers need. -

6 of 14

Declining Weight (DW) Systems

Sackett-Waconia

Sackett-Waconia DW systems are built for flexibility, high tonnage, precision, and reliability. They include heavy-duty stainless-steel hoppers and structure and feature the original Mesh Chain Feeder for gentle handling of material and accurate dosing. The company’s coating system is available for adding liquids or nutrient stabilizers. DW Systems can include additional hoppers for micronutrients or Wolftrax powdered micronutrients. Typical systems operate at instantaneous speeds of 200 tons to 300 tons per hour. -

7 of 14

Direct Drive Blender Series

Adams Fertilizer Equipment

The Adams Direct Drive Blender Series has one of the fastest blending times on the fertilizer equipment market today. Thirteen tons from the weigh hopper to the blender in 90 seconds and 13 tons from the blender to load out in 210 seconds. Adams Direct Drive blenders must have a minimum 36-inch conveyor belt to handle the discharge volume. A 24-inch stainless-steel internal mix auger comes standard. A quality blend with fast in and out means more loads each day for your business. -

8 of 14

Powder and Liquid Blend Systems

AGI Yargus

The Laycote 400, a Dual Ribbon Auger, is a high-capacity coating system that is designed to mix fertilizers and coat liquids and powders quickly and effectively in a continuous blending or coating process. The high-capacity Laycote Dual Ribbon Auger is designed to coat at a maximum capacity of 400 tons per hour (TPH) of urea, although initial R&D testing by the Yargus Engineering Group has shown the capacity to top off at 430 TPH. A smaller-capacity option is also available with the Laycote 200. It can meter out product and coat at rates up to 200 TPH. The Laycote 200 comes complete with a single-ribbon auger and spray system, all controlled with a Layco-Pro Automation built and programmed PLC control panel. -

9 of 14

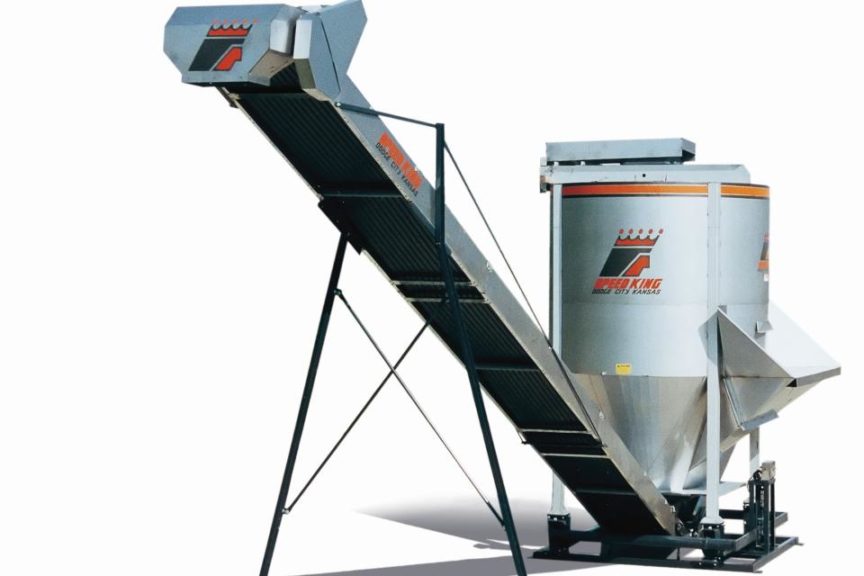

On-Farm Blend Systems

Crustbuster/Speed King

The secret to the Speed King revolutionary blender is the large diameter tapered mixing screw. It gently but quickly draws material into the mixing vessel from the load hopper. No feeder screw is required. Each flight of the tapered screw is gently moving material into a downward flow, creating a very intense and complete mixing action as it virtually eliminates product degradations. -

10 of 14

Bulk Fertilizer Terminals

Sackett-Waconia

Sackett-Waconia offers a full line of high-capacity equipment for Bulk Fertilizer Terminals. Receiving systems range up to 1,200 tons per hour (TPH) or more and can include the capability to unload an entire rail car at once. High-speed loadout systems operate up to 800-plus TPH and offer the ability to fill outbound traffic without the need to re-index. Systems can be designed and built to exactly fit a customer’s needs. -

11 of 14

Multi-Blender DW

Ranco Fertiservice

The Ranco Multi-Blender DW promises fast, accurate, and continuous-flow blending. Its declining weigh technology monitors the output of each product during blending and continually adjusts for any variability caused by density or flowability changes. Controls are computer-compatible, and the entire system is easily expandable for future growth. Ranco’s new drag chain meter units provide high-speed load-out of straight product along with the lower rates required for prescription blends. -

12 of 14

Autobatch/Declining Weight Blend Systems

Doyle Equipment Manufacturing

Doyle’s trademarked AutoBatch and new Declining Weight systems come in configurations that include up to 16 bins that consist of 8-, 10-, 13-, and 16-ton product bins, micronutrient hoppers, and liquid impregnation products on legal-for-trade scales. They offer fully automated and software integration operation or manual operation functionality, with 540 ton-per-hour load-out capability. -

13 of 14

Declining Weight Blend System

AGI Yargus

The flagship blending system for the AGI Yargus product line is the fully automated Declining Weight Blender, ran by Layco-Pro Automation. The advanced technology of the DW system results in a blending system that is one of the most accurate and fastest available today. The Layco-Pro Automation Team consists of dedicated in-house technicians who have developed the unique DW Software Program. Unlike other automated blending systems in the market, DW systems provide a variety of enhancements over many other systems, including remote operational capabilities utilizing Layco-Pro Automation utilizing the Apple iPad, reporting, diagnostics and software updates via a dedicated Ethernet connection. -

14 of 14

Rotary Drum Blender

AGI Yargus

The AGI Yargus 13- and 16-ton capacity Rotary Drum Blender has one of the highest capacities in the industry. The 38-inch stainless-steel mixing auger comes standard in the 13- and 16-ton Rotary Drum Blenders to enhance the mixing action. The large diameter trunnion ring and the 23,000-pound-capacity trunnion wheels carry the load for smooth and efficient running and better weight distribution due to the modified location of the ring. The discharge features one of the fastest discharge rates in the industry — a fast 6 tons per minute. Engineered for durability and low maintenance, the rotary drum’s solid construction will assure you years of dependable service. All outside seams are double-welded for strength and durability. From the steel reinforcement plate to the direct drive gearbox, the Rotary Drum Blend System is the fastest option for batch blending today.

View all

InterSystems Dry Fertilizer Blending System

Low Pro Minuteman

Tower Blend System

Decline-N-Weight Blending System

Precision Fertilizer Blending (PFB) Systems

Declining Weight (DW) Systems

Direct Drive Blender Series

Powder and Liquid Blend Systems

On-Farm Blend Systems

Bulk Fertilizer Terminals

Multi-Blender DW

Autobatch/Declining Weight Blend Systems

Declining Weight Blend System

Rotary Drum Blender

Subscribe Today For

In today’s complex and fast-paced crop production sector, the team at CROPLIFE keeps 21,000 agricultural retailers, distributors and their suppliers up to date on such decidedly 21st century issues as seed technology, biotechnology, precision agriculture, customer service and retention, and business management. See all author stories here.