Retail Remedies: The Desire for Fertilizer Blending Software Integration Continues

Editor’s note: This article is part of CropLife’s new series called Retail Remedies. In Retail Remedies content, we offer solutions and strategies for ag retailers to present to their grower-customers to make dealing with all the uncertainty of the 2022 planting season more manageable. This will include stories on product segments — like the fertilizer blending software feature below — that can help growers stretch their hard-earned dollars in this time of higher crop input costs.

As the 2022 growing season gets underway, the agricultural world is facing myriad challenges, from product shortages in multiple categories to the perpetual quest to find/keep workers. Yet, through all this, one trend remains constant — the desire for blending software systems to help facility operations.

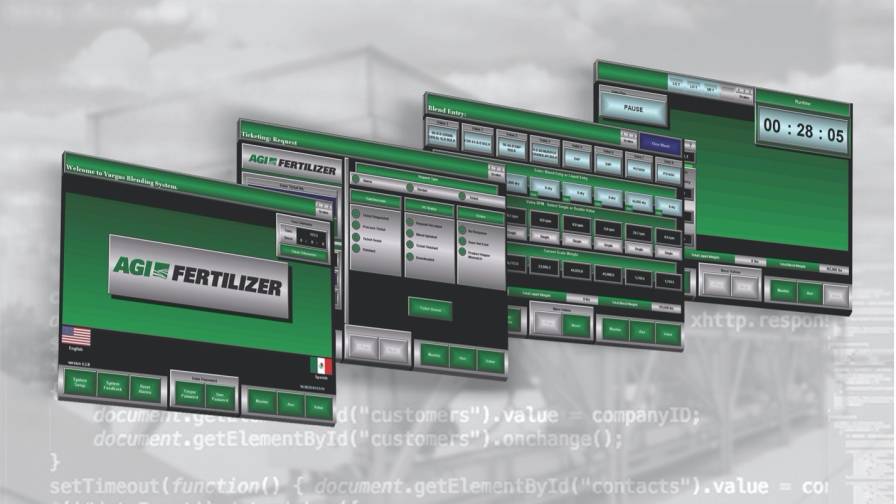

“The market for blending software and integration is strong,” says Jason Boyles, Director, U.S. Commercial Sales for AGI Fertilizer Systems. “The demand for qualified labor, sky high raw material pricing, and very fast farm-level planting technology continue to press the industry for higher customer service speeds and accuracy. At the same time, margin pressure and capitalization requirements demand very efficient methods for running higher volumes of materials through a blend location. The demand for products that improve in-field agronomy and ‘in-blend plant margins’ is gigantic and presents a huge demand for efficiencies.”

Todd Scobie, Sales and Marketing Manager at Murray Equipment Inc. (MEI), agrees. “Between aging facilities, agribusiness consolidation, and increased competition, there is a steady stream of companies looking to improve their fertilizer blending operations,” says Scobie.

In 2022, there are a few additional issues that have come into play impacting the marketplace. “One of the biggest challenges in 2022 will remain supply chain issues,” says Nate Wittmaack, President/COO for Ranco Fertiservice, Inc. “Many system upgrades require updating electronics. We continue to see difficulty in sourcing components and long lead times from manufacturers.”

In turn, this has led to supply shortage and rising prices for many crop inputs, including fertilizer. However, says Wittmaack, this hasn’t necessarily dampened the demand for blending software systems as a result. Quite the opposite, in some cases, he adds.

“We believe higher fertilizer prices place increased attention and scrutiny on inventory levels, projections, and logistics,” says Wittmaack. “All of these factors tend to push ag retailers and wholesalers to look for ways to more effectively control all facets of the logistics supply chain. From an equipment and software standpoint, this can mean increased demand.”

AGI Fertilizer’s Boyles also sees higher fertilizer prices as a potential positive for blending software market fortunes. “For example, the inventory management functions can reduce shrink and maintain blend accuracy in such a way to shave percentage points from high priced ingredients,” he says. “A half-percent improvement in accuracy can net between $50,000 and $70,000 per year for an average plant location with today’s prices.”

The Systems That Can Help

As for the blending software systems available to ag retailers, there are several options to pick from. For example, AGI Fertilizer offers a blending software package called SureTrack Plant Manager. “Our automation has the ability to run the blenders and receiving systems and monitor their speed and accuracy, as well as monitor for maintenance or potential downtime interruptions,” says Boyles. “The robotics software can then display and convey this information to the plant operators onsite or integrate into a customer’s existing software packages for ticketing and order processing. Depending on customer’s scopes, our systems can be run remotely, wirelessly, or directly at the blender location.”

Ranco’s MeshDCS blender control system.

From Ranco, there is the baseline blender control system called MeshDCS. “This system operates as a point-of-use system that allows the user to enter desired pounds for a blend into the control computer and execute a blend,” says Wittmaack. “This functionality is present on every DW Blend System that we sell. This provides a significant ‘fallback’ in many cases. If there is concern about integrations and programming issues, infrastructure network problems, or computer failures, the Ranco MeshDCS embedded blend control system is a great approach.”

At MEI, the system is called ICS ControlPro. “ICS ControlPro software automates the complex procedures of both liquid and dry blending,” says Scobie. “It can handle multiple locations, agronomy software packages, departments, and companies. It manages blending, tickets, customers, drivers, equipment, inventory, and more.”

According to Mike Barringer, Agronomy Support Manager for Software Solutions Integrated (SSI), the company’s Agvance Blending is another such system.

“It allows customers to interact with the company and view all of their account activity in one place via any device,” he continues. “Enabling this kind of digital engagement and interaction has been critical for our retailers to stay connected to staff and their customers over the last two years during the pandemic.”

See all Retail Remedies content here.