A&B Welding Builds A New Liquid Terminal Hub For Briggs Crop Nutrients

To build its new hub facility, Briggs Crop Nutrients enlisted the help of A&B Welding. The result, an efficient facility that allows them to expand their footprint within the marketplace.

-

-

1 of 11

The new liquid fertilizer facility for Briggs Crop Nutrients at Columbia City, IN, has the ability to load out both fertilizer and crop protection chemicals.

-

2 of 11

The building uses solid core energy panels from Energy Panel Structures, Inc. for the main construction to allow the building to be very energy efficient.

-

3 of 11

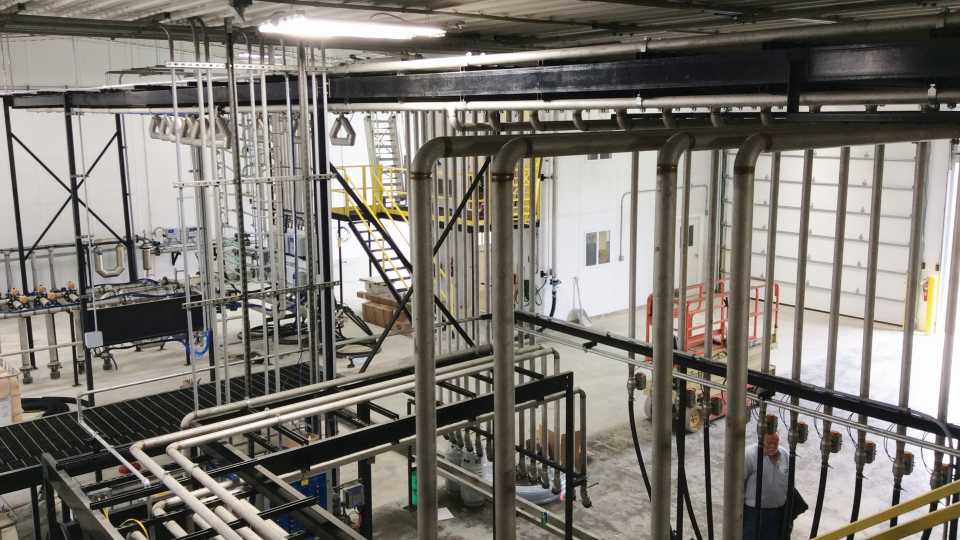

Effecient piping design is possible using underground piping and overhead support structures.

-

4 of 11

The products are piped independently to make sure there is no cross contamination.

-

5 of 11

A pipe rack with walkwaystairs allows the operator to easily access the chemical tanks and keeps all the piping up and out of the way.

-

6 of 11

Chemicals can also be dispensed via pistol grips located in the bay as well as into cage tanks via a repack station.

-

7 of 11

The facility has three bays which can load out fertilizer mixes as well as hot load chemicals directly into the mix. Small additions are measured via a weigh pot.

-

8 of 11

The fertilizer bays have the ability to move product at a rate of 600 gallons per minute into each of the three load out bays using either top or bottom fill options.

-

9 of 11

Elevated control room provides easy access to loading trucks in both bays.

-

10 of 11

The facility is automated using the latest recipe based software which allows the entire plant to be operated from a single touch screen.

-

11 of 11

The facility is a unique design which A&B Welding has developed over many years of constructing liquid load out facilities.

View all

Sims and Mize

What They Needed

Ag Plus, LP was facing challenges meeting customer demands with the changes that have taken place in Agricultural Industry in recent years. General Manager Jeff Mize and Agronomy Manager Mike Sims knew something had to change if they wanted to stay competitive in the changing marketplace. They decided the best solution was to consolidate three facilities into one centrally located hub so Ag Plus partnered with CHS to form the company Briggs Crop Nutrients, LLC in Columbia City, IN.

“The real reason we went with the liquid fertilizer and crop protection hub was for speed and efficiency, inventory and shrink control, and developing a building that will help us meet the changes taking place in agriculture with our producer base in our area,” said Mize. “We’re consolidating three facilities into one gaining loading times, controlling inventory shrink and becoming much more efficient.”

What We Designed

A&B Welding, LLC, an industry leader in designing and building liquid fertilizer terminals and API650 tanks, helped Briggs Crop Nutrients design a new liquid terminal hub.

Kiel

“We worked with Briggs Crop Nutrients to engineer a plant that would meet their current needs while also allowing for future growth,” said A&B Welding President Arlin Kiel.

As a result the new fertilizer hub has the capability of moving product at a rate of 600 gallon per minute into each of the three loading bays using either top or bottom fill options. This translates into an average of (12-15) 25 ton loads per hour.

Subscribe Today For

Hopkins is Senior Online Editor for the CropLife Media Group at Meister Media Worldwide. See all author stories here.