How Waconia Helped Three Cooperatives Increase Their Efficiency

Efficiency and reliability were crucial for three companies — Sunrise Cooperative, Edon Farmers Co-op and Cedar Country Cooperative — looking to modernize equipment and increase capacity.

What Sunrise Cooperative Needed

Sunrise Cooperative in Norwalk, OH, had outgrown its current equipment and storage facility. The company knew the new plant had to improve turnaround time and accuracy, because its customers didn’t want to wait in line for product or paperwork.

Tony Myers, location manager, was very happy with the system Waconia installed. “With our old volumetric system, we had to constantly recalibrate,” he said. “With the new Waconia equipment, the need to recalibrate has been eliminated, and we no longer need to verify our loads on a platform scale. Big timesaver! The new Waconia equipment is really versatile, too. We do impregnations per customer requests and have added a small seed blower. Waconia helped us with start-up, their prices were fair and the system they installed has been working really well. Waconia did a great job!”

What Edon Farmers Co-op Needed

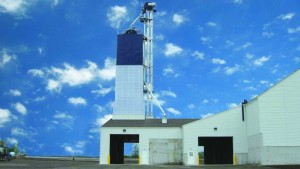

Edon Farmers Co-op in Edon, OH, started planning its new facility three years ago, because the rising operating costs and upkeep of its three existing facilities made it impractical to consider them going forward. The company decided on a new 7,000 ton plant and selected Waconia Manufacturing to provide the fertilizer blending and handling equipment.

Rick Dunbar, general manager, had already used Waconia equipment in several plants, and was pleased with their quality and dependability. “Waconia’s bids came in great, and they helped us go through 15 to 20 changes without complaining,” he said. “The equipment arrived as scheduled and we were up and running. If we had to do it all over again, I don’t think we’d change a thing.”

What Cedar Country Cooperative Needed

Cedar Country Cooperative in Elk Mound, WI, was having a hard time keeping up with customer demand. “Every spring, farmers are getting faster at planting their crops, and we couldn’t keep up,” said Travis Berg, Agronomy Division manager. “We’d heard good things about Waconia from other customers, so we gave them a call. Waconia took us to some existing plants so we could see their equipment, talk with their customers and discuss options first hand. They gave us some really good recommendations!

“With our new plant, we’ve significantly increased the speed of product delivery, which has helped us add new business and take pressure off our other plants. Now we can unload a semi in under eight minutes, compared to 40 minutes with our old system. And blend time for 24 tons is less than 15 minutes, it used to take 50.”