Maple River Grain & Agronomy Phases In Site Development With Marcus Construction

Marcus Construction helped Maple River Grain & Agronomy in Casselton, ND, with the design-build of its dry fertilizer, liquid chemical/seed storage, treatment/maintenance shop and flat grain storage facilities over a six-year period.

-

-

1 of 14

The activity at the Maple River Grain & Agronomy (MRGA) site in Casselton, ND, is really impressive with all the product they offer their customers.

-

2 of 14

MRGA was formed in 2004, after which the Board of Directors and management team put together a strategic plan for capital projects.

-

3 of 14

As MRGA continued to add to their site, the Marcus Construction in-house design team was able to help with building expansions and traffic patterns.

-

4 of 14

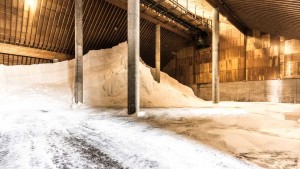

Marcus Construction’s dry fertilizer design offers a spacious and unobstructed alleyway (bin gates are flush with the wall) allowing for easy maneuvering and alley clean up.

-

5 of 14

Another look at the alleyway.

-

6 of 14

MRGA’s six main storage bins are well lit from the light panel wall above.

-

7 of 14

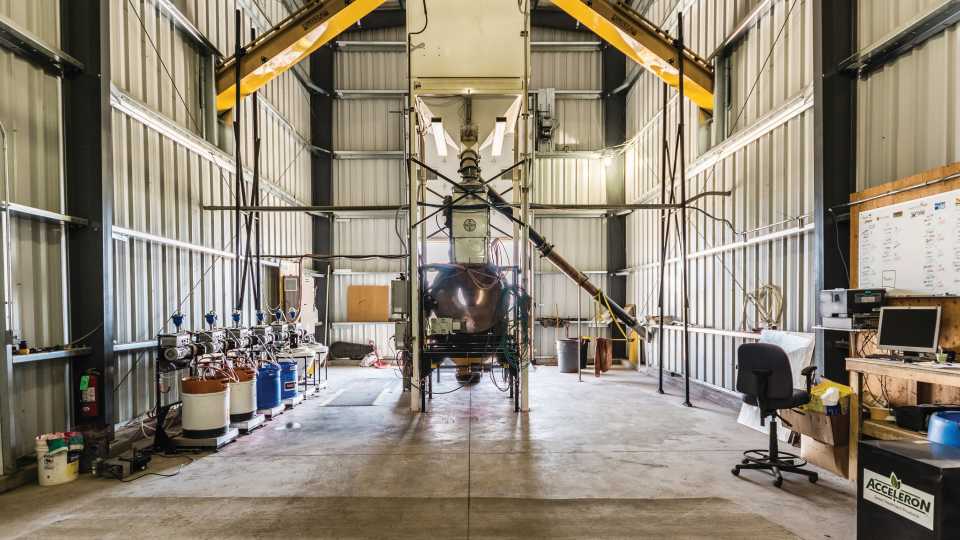

Unique to MRGA is an elevated break room above a reclaim tunnel, and right next to the control room, where the company also has convenient access to its micro bins.

-

8 of 14

MRGA’s chemical tanks have a secondary containment dike as well as continuous containment around the entire building.

-

9 of 14

Another look at the chemical tanks.

-

10 of 14

The seed warehouse has plenty of room for packaged storage.

-

11 of 14

The seed warehouse also has space for the seed treating area.

-

12 of 14

Complete maintenance shop with offices and full service capabilities.

-

13 of 14

MRGA’s flat grain storage is constructed of Continuous Truss - Open Web with two interior columns.

-

14 of 14

The corn is moved by a 60,000 bushel per hour tripper conveyor with catwalk.

View all

What They Needed

Maple River Grain & Agronomy, LLC (MRGA) was formed in 2004, after which the Board of Directors and management team put together a strategic plan for capital projects. Marcus Construction was brought in early to help execute MRGA’s strategic plan and continues to be a great partner, recalls Alex Richard, Grain Division manager with MRGA.

“Marcus helped put together a site design that was implemented in phases over a six-year period,” Richard said. “The Design-Build projects have expanded with our growth and we have been pleased with our relationship with Marcus, what they put together for us really allows us to operate efficiently.”

What We Designed

“At Marcus Construction building relationships is the key to our success,” explains Randy Wright, Marcus Construction, business development. “Maple River Grain & Agronomy, LLC, Casselton, ND, is just one example of this kind of relationship. In 2008 MRGA came to us for help in designing a dry fertilizer facility. We spent a great deal of time with the MRGA team to get a clear understanding of what they wanted to accomplish, including future expansion options and how the site would look in five years. Those discussions led to Marcus designing the first facility, a 36,000 ton dry fertilizer building with unit train capabilities, as well as retail blending and wholesale operations.

“In 2012, the next project came to life, a 48,936-square foot facility that housed liquid chemical and package storage, seed storage warehouse and treatment area, with a large maintenance shop. We designed a facility to accommodate all of these operations under one roof, allowing MRGA to serve customers quicker and with greater staff efficiencies.

“In 2014, we finished our most recent project for MRGA, a 3.9 million bushel flat grain storage facility. It’s been three outstanding projects for a great customer and a real compliment to have them come back to us for multiple projects. Our thanks to MRGA for the great relationship.”

Subscribe Today For

Hopkins is Senior Online Editor for the CropLife Media Group at Meister Media Worldwide. See all author stories here.