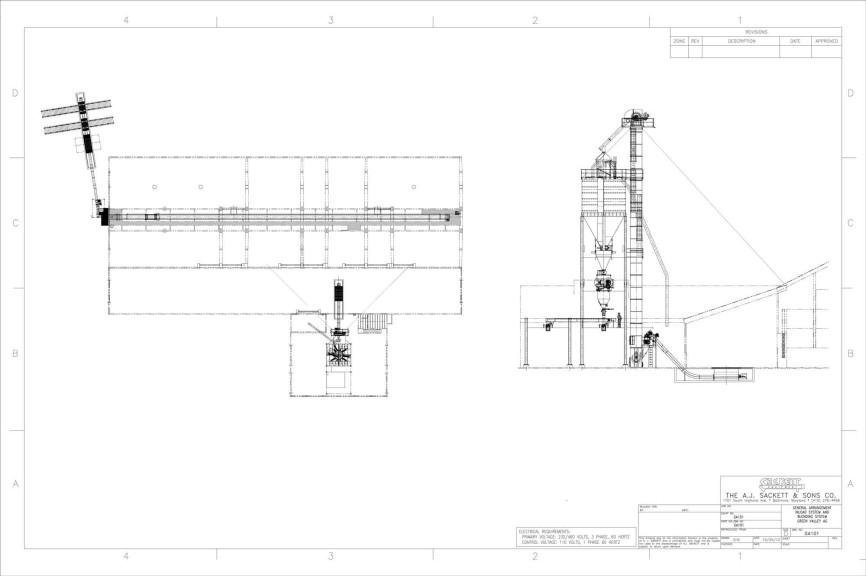

Green Valley Ag Adopts A.J. Sackett’s Precision Fertilizer Blending® Technology At New Facility

Sackett’s Precision Fertilizer Blending® Technology is making huge strides around the world. Green Valley Ag adopts the technology at its new facility to support its advancing agronomic needs.

-

-

1 of 10

Green Valley Agricultural’s new facility can serve as a hub plant for many of the company’s locations.

-

2 of 10

Green Valley Agricultural’s new facility can serve as a hub plant for many of the company’s locations.

-

3 of 10

The HIM Mixer represents the heart of the GVA fertilizer system.

-

4 of 10

A view of the A.J. Sackett surge hopper at the GVA facility.

-

5 of 10

An inside look at the A.J. Sackett weigh hoppers at the GVA plant.

-

6 of 10

A truck of urea coated with nitrogen stabilizer using A.J. Sackett's PFB technology.

-

7 of 10

Scouting a soybean patch. At Green Valley Ag, the facility is not only interested in blending fertilizer, but seeing how these blends perform in the field.

-

8 of 10

The facility fills the building with a 300TPH Sackett receiving system.

-

9 of 10

The facility uses a reclaim system with easy to access, above ground, conditioner.

-

10 of 10

Small, pull-behind spreaders or 50-ton trucks can load precision-blended fertilizer quickly and accurately

View all

What Green Valley Ag Needed

Mark Edema and John Christian of Green Valley Ag

The first meeting with Green Valley Agricultural (GVA) was in March 2012. Sackett personnel had the chance to meet with partners John Christian and Mark Edema at their offices in Caledonia, MI. We spent time doing crop research to access the needs of growers in the area. We learned GVA is the preferred fertilizer supplier for this area’s vegetable industry and works closely with the area’s most progressive row crop and fruit growers. A diverse range of crops are grown in western Michigan including vegetables, edible beans, tree fruits/forages, corn, soybeans and wheat.

We knew that crop diversity meant many ingredients would be added to the fertilizer blends. Batch sizes could be small to very large, and customers would expect very high quality blends.

What A.J. Sackett Designed

Charles Formisani of A.J. Sackett

With the customer’s goals defined, Sackett engineered each system to meet those needs. It was determined that a Precision Fertilizer Blending Tower would best meet GVA’s needs. The tower features our High Intensity Mixer (HIM), offering both the accuracy and quality the company needed for specialty growers and advanced crop nutrition and the speed needed to service the variety of growers. Additionally, the blend tower provides extremely high output of straight materials and substantial storage overhead to serve as the hub plant for GVA’s retail locations.

The engineering, fabricating and installation process took us several months. We worked closely with Marcus Construction on the building design and Murray Equipment on automation. The plant was started in December 2013.

It’s incredibly satisfying for us at Sackett to see GVA running so efficiently and keeping its customers and truckers so happy.

For more information, visit www.AJSackett.com.

Subscribe Today For