KAHLER AUTOMATION

WHAT THEY NEEDED

United Farmers Cooperative’s (UFC) prior agronomy center was approaching 30 years old and needed to be upgraded in size and efficiency to better serve its customer base. In constructing its new fertilizer/chemical building in Farragut, IA, UFC wanted two load-out bays capable of simultaneously and accurately dispensing fertilizer to each bay, as well as bulk chemicals and water. Mini-bulks and hand-adds would be dispensed through a weigh tank, and all measuring devices needed to be legal-for-trade. All systems would have to be integrated, including moving orders electronically, and the entire site had to be in a position to expand operations in the future.

-

-

1 of 11

United Farmers Cooperative in Farragut, IA facility features two bays to provide dispensing for fertilizer and chemical and 24/7 unstaffed dispensing.

-

2 of 11

For ultimate system flexibility chemicals can be dispensed to mini bulks in the repack area and at the same time delivered to each bay for premixed loads.

-

3 of 11

UFC’s control room is integrated with Terminal Management TMX software to process orders and manages all data associated with plant operation. Plant Supervisor PSX software does the actual dispensing of product from the blend order.

-

4 of 11

Hands adds can be quickly added in the 130 gallon weigh tank with weights recorded automatically.

-

5 of 11

In-bay controls allows the operator to start and pause orders as well as get notified when an air purge completes the loadout process.

-

6 of 11

UFC uses the latest fluid reading technology to simultaneously dispense and provides two to three times more accuracy and speed.

-

7 of 11

Driver checking in with the Self Serve 2 system. This allows selected operators to receive product at the location, unstaffed, 24 hours a day. Legal-for-trade mass flow meters measure all products to be dispensed.

-

8 of 11

The United Farmers Coopertive -Farragut, IA, team includes (from left): Brad Maher (Agronomy Operations Manager), Larry Schniepp (Location Manager / Agronomy Sales), Kris Spears (Customer Service/Agronomy Accounting), Ron Tvinnereim (Asset Manager) and Greg Herzberg (Sales Agronomist).

-

9 of 11

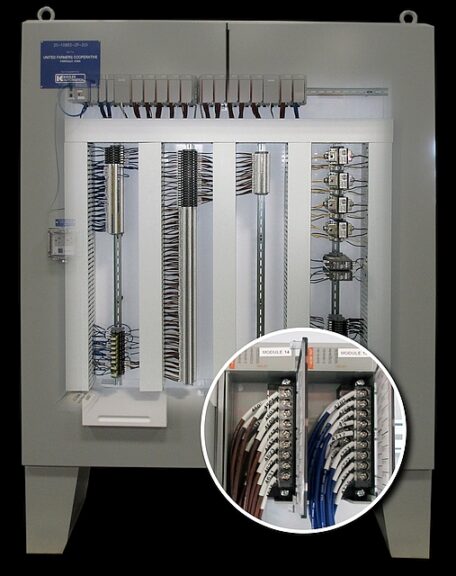

Kahler Automation provides turn key quality solutions for motor controls.

-

10 of 11

UFC’s custom built and programmed KA-4000 system controls 57 product destinations and 18 measuring devices and was factory tested to ensure high dependability and uptime.

-

11 of 11

Water level is maintained automatically.

View all

WHAT WE DESIGNED

The Farragut facility’s two bays provide bulk chemical from 12 tanks, measured with mass flow meters; Bay 2 is capable of 24/7 unstaffed dispensing. Chemicals can be dispensed simultaneously to each bay for premixed loads, and also service mini-bulk repack needs. Mini-bulk chemicals are piped to a 130-gallon weigh tank on a deck scale; the weigh tank can also be used to accommodate hand-add products. All product-dispensing systems are controlled with a central custom PLC panel and 10-inch slope-front touchscreen Human Machine Interface (HMI). Kahler Automation’s Terminal Management TMX software processes orders from UFC’s agronomy package, and manages all data associated with plant operation. Our Plant Supervisor PSX software does the actual dispensing of product directed from the blend order. For afterhours dispensing in Bay 2, Kahler’s Self Serve 2 software dispenses orders.

Subscribe Today For

Kahler Automation designs control systems for dry material handling, liquid product handling, grain flow control, and industrial innovations. See all author stories here.