Marcus Construction Designs New Liquid Fertilizer Facility for Morral Companies

What They Needed

The existing production facility, built in 1980, was showing its age. Morral Companies had outgrown the building, and routine maintenance had become difficult, with tight spaces and multiple hoses and piping at floor level. Morral needed a larger, more efficient building with all functions under one roof, including truck receiving, dry bulk storage, liquid storage, blending operations, dry bulk truck load-out, van receiving/loading, and pallet storage.

-

-

1 of 13

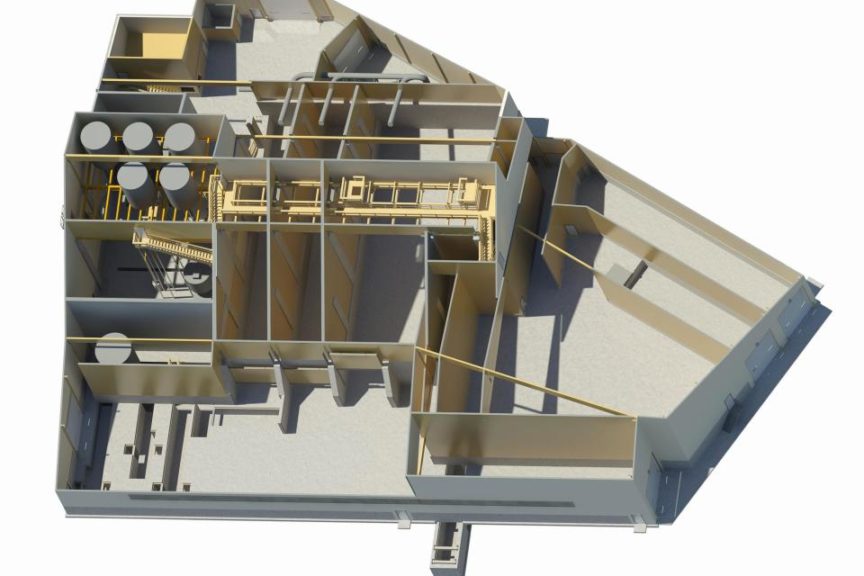

Overhead view of the completed Morral Companies building shows the pie-shaped, tight building site. Restrictions included an existing building and tank farm to the south, CSX main line to the east, CSX easement to the north, and city street with overhead power lines to the west.

-

2 of 13

Morral Companies new Liquid Fertilizer Manufacturing Facility in Morral, OH, designed and built by Marcus Construction.

-

3 of 13

This rendering shows the floor plan of the new Morral facility. The irregular-shaped building has multiple pits and conveyors and strategically placed tanks, piping, and conveying equipment.

-

4 of 13

The building includes a second level mezzanine that houses six 5,000-gallon liquid tanks for input in the blending process.

-

5 of 13

The building design required an extensive stair and catwalk system to access all key areas and equipment.

-

6 of 13

Large translucent light panels provide plenty of natural light to the overhead conveyor and tripper that fills the three dry bulk bins. Plastic curtains are utilized at the conveyor and catwalk to minimize dust and contamination between bins during filling.

-

7 of 13

A custom built platform and catwalk system allows easy access to the liquid mixing tanks.

-

8 of 13

Morral included a dust collection system to provide negative pressure when filling dry bins to minimize the dust in the building.

-

9 of 13

There is approximately 4,000 square feet of pallet and packaged storage with convenient access to the truck/van dock and forklift ramp.

-

10 of 13

This nearly completed construction photo shows a stacked control room and electrical room next to a fireproof wall that houses Morral’s liquid fertilizer and blending tanks.

-

11 of 13

The water tank and dry bulk handling equipment feeds the mixing tanks.

-

12 of 13

The building was designed with a wide alley-way allowing for multiple unload pits and specially designed bin gates to eliminate product contamination. Key areas enjoy natural light courtesy of translucent wall panels.

-

13 of 13

There are three covered truck lanes including a truck and rail bulk receiving (with a 35’ clear height to accommodate rear tilt trailers), a truck bulk load-out and this one shows a truck dock for packaged product loading/receiving.

View all

What We Designed

Marcus Construction designed a state-of-the-art production facility that will allow Morral to provide more products in a much more efficient manner. One of the most challenging aspects was fitting the building in the desired location. It is a pie-shaped area with existing buildings and a tank farm to the south, CSX main line to the east, CSX easement to the north, and a city street with overhead power lines to the west. The design called for an irregular-shaped building, and Marcus’ Pre-Construction Team did an outstanding job maxing out the available square footage. Another challenge, because it was on a main rail line, was that the rail receiving pit needed to be installed in one day — this was successfully completed with an engineered precast unit.

Subscribe Today For

In today’s complex and fast-paced crop production sector, the team at CROPLIFE keeps 21,000 agricultural retailers, distributors and their suppliers up to date on such decidedly 21st century issues as seed technology, biotechnology, precision agriculture, customer service and retention, and business management. See all author stories here.