Murray Equipment Helps Green Valley Ag Design New Fertilizer Plant

Green Valley Ag wanted to increase tonnage and throughput to better serve its customer base. MEI helped the company do that and more.

-

-

1 of 10

Green Valley Ag co-owners Mark Edema (left) and John Christian wanted better inventory control and process improvement with integration into their agronomy software.

-

2 of 10

Murray Equipment worked alongside Green Valley Ag to engineer plants that would help the company achieve its goals while dramatically improving efficiencies, according to MEI Sales Manager Todd Scobie.

-

3 of 10

An aerial shot of the new facility at Green Valley Ag in Wayland, MI. The company wanted rail access and increased storage capacity.

-

4 of 10

The liquid fertilizer loadout at Green Valley Ag can accommodate vehicles from 0.5 to 50 tons.

-

5 of 10

A.J. Sackett and Sons Co. and Murray Equipment came together to build the new automated dry fertilizer plant at Green Valley Ag.

-

6 of 10

The new liquid fertilizer plant at Green Valley Ag included new automation which interfaces directly into the agronomy software at the home office.

-

7 of 10

In the dry fertilizer plant at Green Valley Ag, bin managers can interface with the automation and switch bins with a tablet.

-

8 of 10

Murray Equipment designed the plumbing for Green Valley Ag’s new liquid fertilizer plant.

-

9 of 10

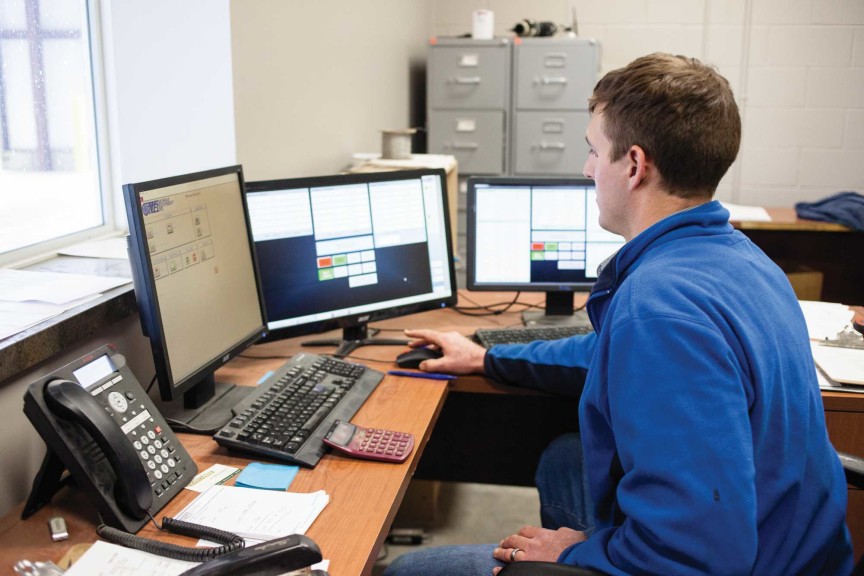

Murray Equipment's dry fertilizer user interface improves oversight and dramatically saves time.

-

10 of 10

The rail in loading system connected to the liquid fertilizer plant at Green Valley Ag can handle up to 10 cars at once.

View all

WHAT THEY NEEDED

In recent years, Green Valley Ag (GVA), located in Western Michigan, realized they were facing growth challenges. During growing season, customers could be in line for one to two hours to receive both dry and liquid fertilizer. No longer was replacing key parts to expand capacity going to work. The company needed a new facility.

With 25 years’ experience, owners John Christian and Mark Edema knew they wanted a long term solution. GVA wanted to leverage as much of their existing staff as possible and limit rapid hiring to staff the new location. The company also wanted better inventory control and process improvement with integration into their agronomy software. “One of the challenges we face is that Michigan is a destination state. Nobody comes through here unless they are going to Michigan. The nearest terminal is 2.5 hours away, so we spend a lot of time burning up the highways,” said Christian.

WHAT WE DESIGNED

Murray Equipment, Inc. (MEI), a leading supplier of liquid handling equipment that boasts an outside sales force with field experience exceeding 100 years, helped GVA design new liquid plant, complete with automation and controls for both its liquid and dry fertilizer plants.

“We worked alongside them to engineer plants that would help them achieve their goals while dramatically improving efficiencies,” said MEI Sales Manager Todd Scobie.

As a result, tickets can be sent direct to the control system via the MEI software from GVA’s agronomy software and upon fulfillment, actual amounts are sent back for billing. The outcome is that tickets that might have required one hour to fulfill can be addressed in 20 minutes.

For more information, visit www.MurrayEquipment.com.

Subscribe Today For

Hopkins is Senior Online Editor for the CropLife Media Group at Meister Media Worldwide. See all author stories here.