Stueve Construction’s Input At Cooperative Elevator Association

To build its new hub facility, Cooperative Elevator employed the help of Stueve Construction (and the aid of several other suppliers).

-

-

1 of 11

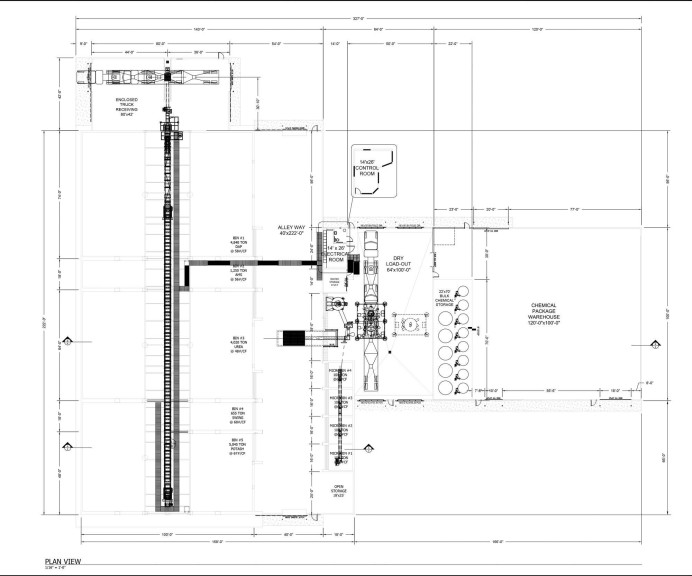

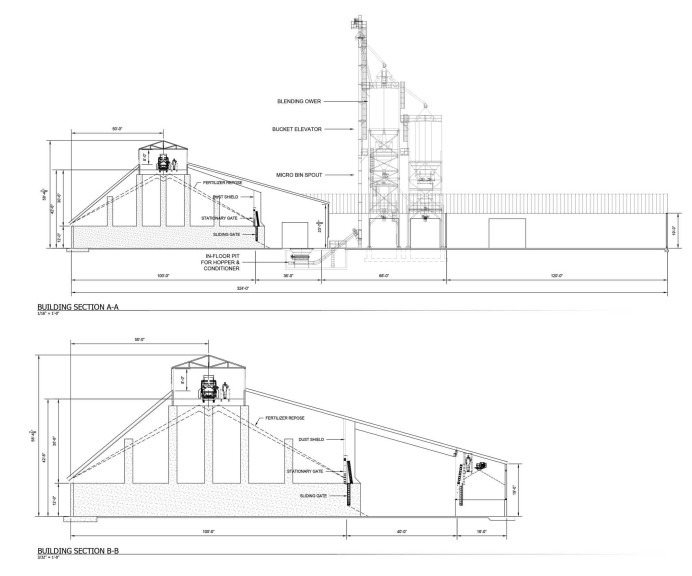

Cooperative Elevator Association's Ocheydan, IA, facility

-

2 of 11

Cooperative Elevator Association's Ocheydan, IA, facility

-

3 of 11

The inside of the dry fertilizer building at Cooperative Elevator features multiple bays for different products and a high sloped ceiling.

-

4 of 11

Exclusive state-of-the art Stueve Construction designed “Vista View” Elevated Control Room.

-

5 of 11

The main control office for the plant features an open floorplan that provides outstanding viewing of operations.

-

6 of 11

Chemical Storage Tank System with Catwalk and step down dike area at Cooperative Elevator recessed in floor for safe and easy access.

-

7 of 11

Enclosed Truck Receiving Area at Cooperative Elevator ensures all loads are weather condition protected.

-

8 of 11

Stueve exclusive: Naturally lit catwalk.

-

9 of 11

Stueve exclusive: Naturally lit bin area at Cooperative Elevator.

-

10 of 11

Spacious “Double Bay” Truck Load Out Area at Cooperative Elevator.

-

11 of 11

The warehouse floor is roomy enough to not only store products, but self-propelled sprayers that are not in use.

View all

What Cooperative Elevator Needed

Rob Jacobs, Dave Muilenburg and Dan Jacobsma, CEA

Our goal was to put together a hub facility that would allow us to better serve our customer’s needs in an efficient and timely manner. Our business is changing and we needed to find ways to bring continued value to our customers and yet enhance our bottom line. We wanted a flexible design concept that was cost effective and allows us to be fully expandable and adaptable to meet our client’s ever-changing needs. Our team (management & operations) toured many existing facilities and looked at several dry fertilizer storage builders and equipment companies before making our decision. We selected Stueve Construction, Waconia Mfg. and Kahler Automation as our project partners. We really valued Stueve’s 55+ years of exclusive dry fertilizer storage construction experience, in-house engineering and overall building features! Steve Anderson, Russ Buscher and Jack Burns listened to our needs and came up with a building solution that more than met our needs and expectations!

What Stueve Construction Designed

Steve Anderson of Stueve

Upon the initial call from CEA, I met with Rob, Dave and Dan to discuss their needs and goals for the project. They wanted to have Stueve assist them with our experience in finding a building solution that could meet the following criteria: Develop a hub facility that can bring operational efficiency to their agronomy program, incorporate key building features that can increase speed and accuracy to their operation and create a storage facility that could store a large percentage of their needs and yet be expandable for future growth. They had logistical issues in the past (rail & truck) in getting fertilizer in a timely fashion to meet their customer needs and application window.

For more information, visit www.Stueve.com.

Subscribe Today For