USC Worked With Gumz Seed Service To Design And Build A New Seed Care System

USC worked with Gumz Seed Service in Central Wisconsin to help design and build a new seed care system, helping the operation to expand its footprint within the agricultural community.

-

-

1 of 14

Gumz Seed Service’s USC seed treating equipment. This versatile set-up allows the facility to pull seed in from outdoor bins as well as boxes for treating. The treated seed can be packaged in tenders, boxes, bags, or whatever the customer wants.

-

2 of 14

Gumz Seed Service chose USC’s Automated LPX2000 treater to grow alongside their new business. This calibratable machine offers the most customized options for any retailer.

-

3 of 14

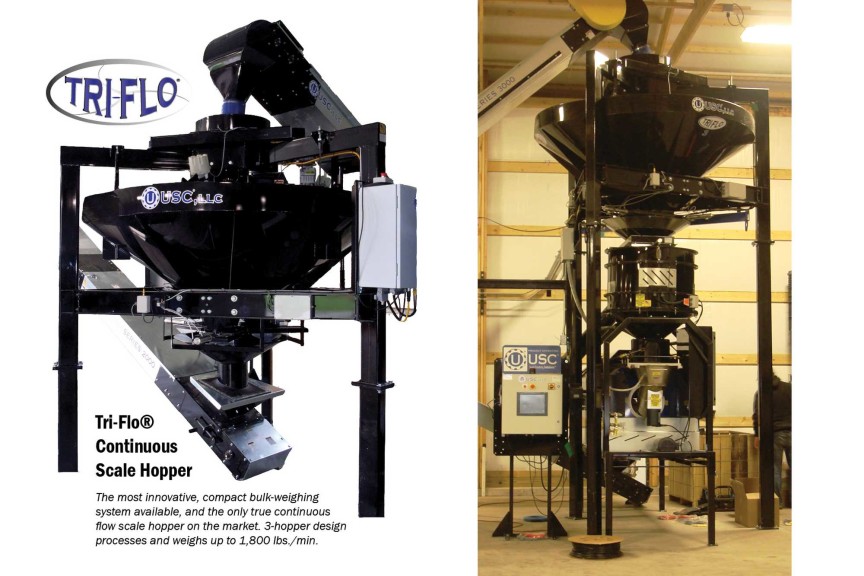

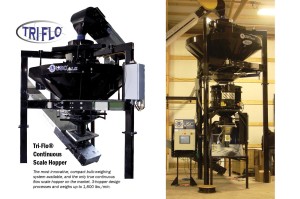

The Tri-Flo® is a must-have for any bulk seed site, offering true continuous processing and an easy add-on to existing sites ready to treat non-stop. Gumz Seed Service had it configured as an above the treater piece, but it can be used on the floor and in corners when space is limited.

-

4 of 14

This floor-level angle shows the treater to the vibrating hopper.

-

5 of 14

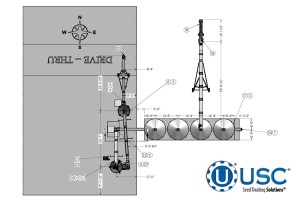

Showing the drive-thru layout, tenders, semis and other trailer options can easily load treated seed inside.

-

6 of 14

USC’s installation crew putting the final touches on Gumz Seed Service’s site. Front view of the LPX2000 treater, Tri-Flo® and single panel automation.

-

7 of 14

The vibrating hopper eliminates bridging and clumping when treated seed sits for longer periods of time. Controls can be operated directly from forklift when using a box-to-box set-up.

-

8 of 14

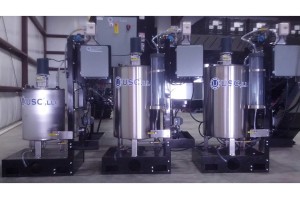

Stainless steel pump stands and mix tanks are the preferred method for mixing. All USC pump stands are configurable – choose material, flow meter, calibration tube and scales for example.

-

9 of 14

USC’s Seed Series Bin Fill Conveyor safely and quickly moves seed from truck to bin.

-

10 of 14

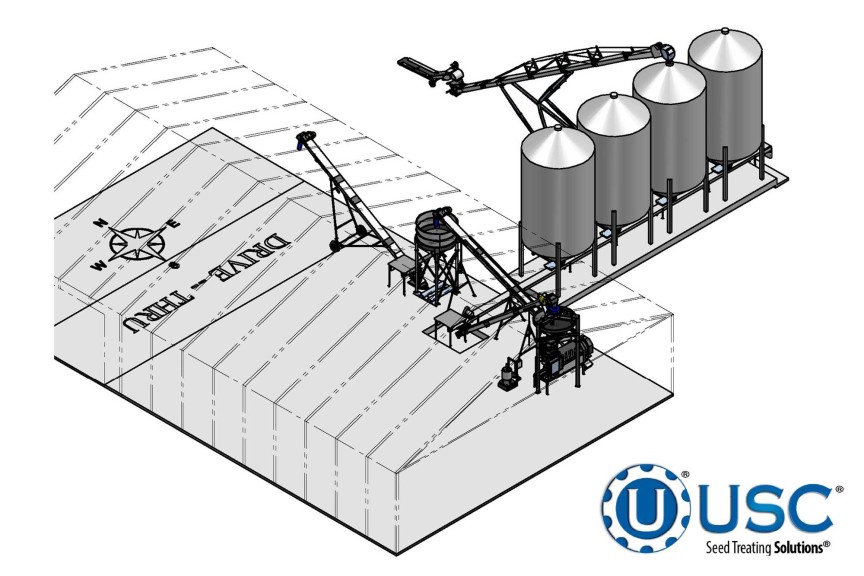

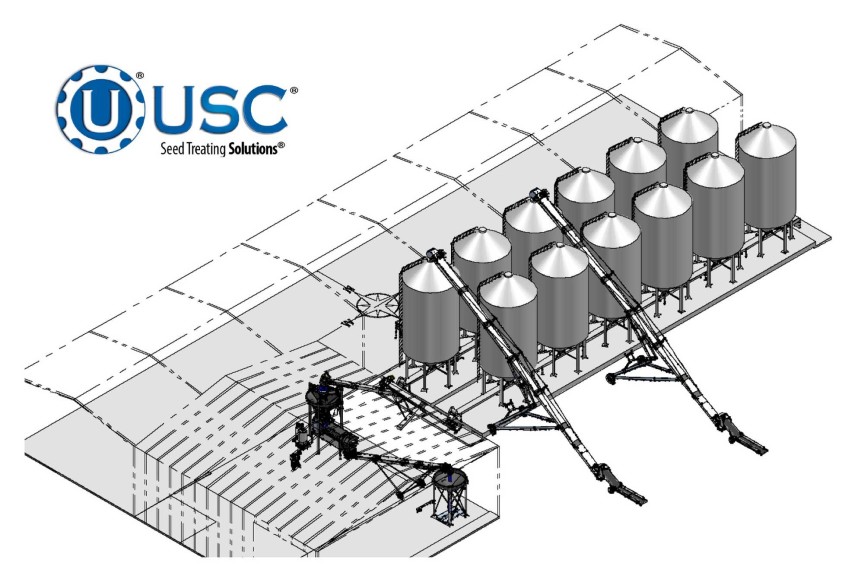

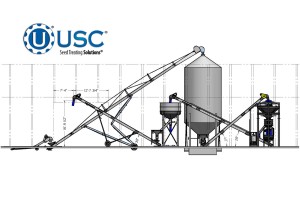

Gumz Seed Service site CAD drawing.

-

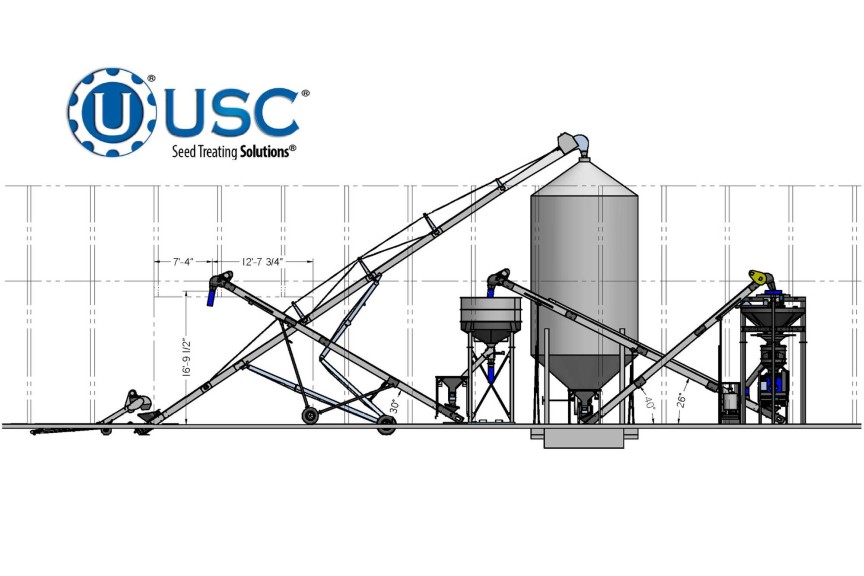

11 of 14

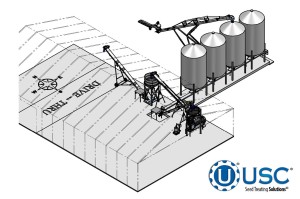

Gumz Seed Service site CAD drawing.

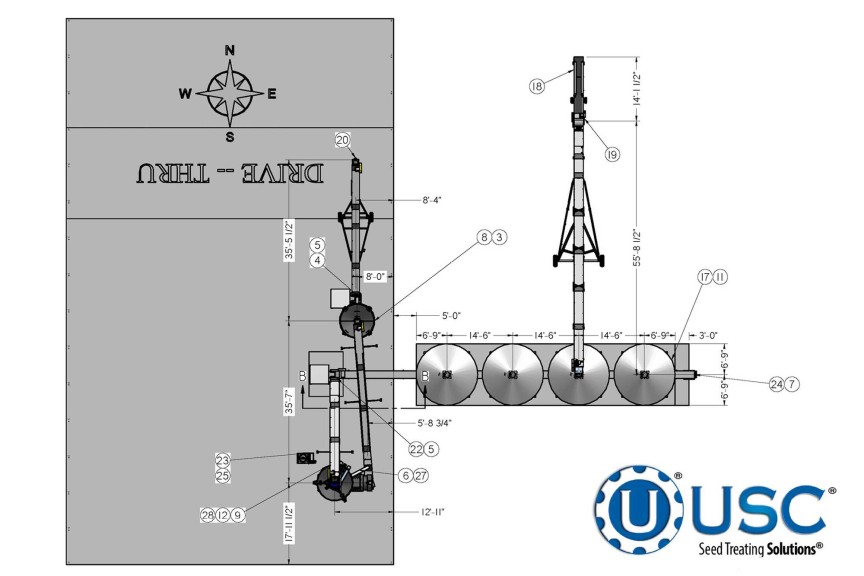

-

12 of 14

Gumz Seed Service site CAD drawing.

-

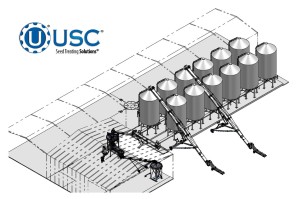

13 of 14

USC’s automation controls up to 20 seed bins, shown is an example with 12, indicating any-sized facility can benefit from USC’s custom design approach.

-

14 of 14

Panoramic view of Gumz Seed Service as seed moves through the equipment into seed tender.

View all

What Gumz Seed Service Needed

Gumz Seed Service’s Richard Gumz

Located in South Central Wisconsin, Gumz Seed Service is a fourth-generation farm under the management of brothers Richard and Roderick. The operation has been farming potatoes, onions, carrots, mint, corn and soybeans since the mid-1990s. In addition to a packing shed expansion project in 2012, the brothers wanted to diversify the business further, so when an opportunity came along to acquire a Pioneer Seed Agency, they jumped on it and Gumz Seed Service was born!

The brothers envisioned an operation that could take a new division of an existing company to the next level. “As a distributor of Pioneer Seed products, we wanted to be able to provide a complete package of seed enhancements,” says Richard. “We understand the benefits of seed treatment and believe that seed treatment will continue to evolve and be a value to the seed agency and producer.”

What USC Designed

USC’s Brett Dallman

Gumz Seed Service’s facility started as a dirt plot with a unique vision to expand and diversify the Gumz brand by offering the latest seed treatment products, services and technology. USC was able to start designing this facility from a blank canvas, with the logistics of each piece of equipment having a special place within the 120- X 72-foot facility.

With ambitious goals for the operation, Gumz Seed Service was condfident this addition would not only bring in extra revenue, but also give a competitive advantage within the region as far as seed treating technology was concerned.

USC was able to translate this vision through a customized approach, making sure the equipment ultimately achieved the desired goals of the business, while staying within budget. Specific details are outlined to the right with preliminary drawings, equipment specifications and USC’s signature bulk site process.

“We’ve always believed in dedicating our resources to provide the best solutions for each USC site,” says Brett Dallman, Western regional manager. “But this was special because the Gumz’s are equally passionate about the future of seed treatment and saw the value in doing it right from the start.”

For more information, visit www.USCLLC.com.

Subscribe Today For