United Farmers Cooperative Gains Efficiency Via Kahler Automation

Kahler Automation helped design a facility that allowed United Farmers Cooperative in Brownton, MN, reach the highest efficiencies in supplying its customers with the products they need.

-

-

1 of 9

Overhead view of United Farmers Cooperative facility in Brownton, MN.

-

2 of 9

The dry fertilizer receive shed for rail and truck.

-

3 of 9

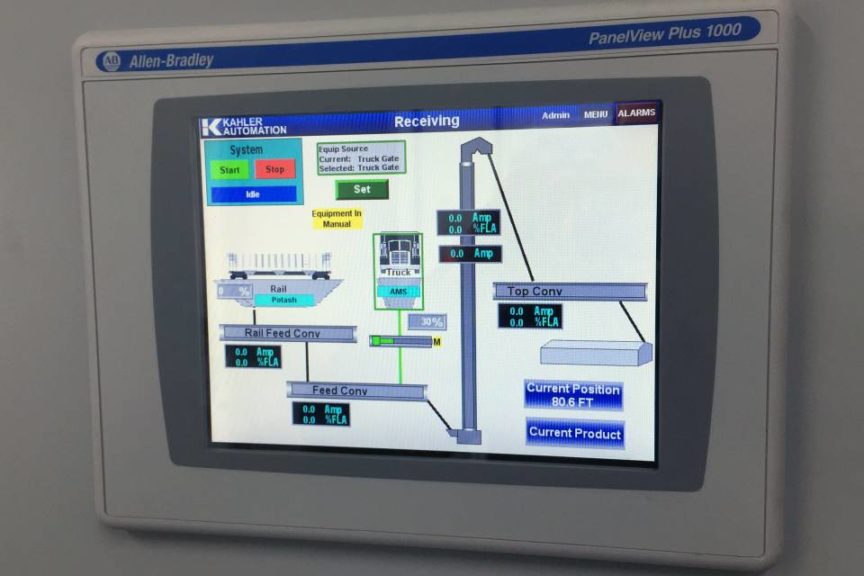

Touchscreen interface for dry fertilizer receiving controls.

-

4 of 9

Kahler technician observing tripper conveyor during installation.

-

5 of 9

Dry fertilizer loadout tower, featuring a Sackett-Waconia H.I.M.mixer.

-

6 of 9

Valves and hand pumps for tote-fill-area (scale not pictured).

-

7 of 9

One-inch mass flow meters for chemical injects.

-

8 of 9

Truck in bay for liquid fertilizer load-out.

-

9 of 9

Liquid chemical tanks surrounded by dike.

View all

WHAT THEY NEEDED

“Our goal at United Farmers Cooperative in Brownton was to reach the highest efficiencies in supplying our customers with the products they need, making this a world-class fertilizer and chemical facility. Kahler Automation’s assistance in designing the facility helped make that happen.

“Kahler’s controls and their automation systems made this the most efficient facility in the Midwest. I can go on and on about how well their system is working. Functionality such as the reports and daily logs that I can pull from Kahler’s software, and being able to look forward with everything allocated in the queue, has been great. We’re very happy.”

— Dave Eckhoff, Vice President of Agronomy, UFC

WHAT WE DESIGNED

In collaboration with Sackett-Waconia, a 200-ton blend tower with 4-ton high-intensity mixer (H.I.M.) was developed; a liquid impregnation system was designed by Kahler. An accompanying straight product tower allows wholesale trucks to be loaded quickly.

A custom chemical and liquid fertilizer facility was designed for prescription blends to be made. Both straight product and hot loading is available.

To meet United Farmers Cooperative’s lofty efficiency goals, Kahler Automation’s designs included a 24/7 unstaffed load-out bay, with technology allowing UFC customers to pick up scheduled fertilizer orders at any time, day or night.

Subscribe Today For

Hopkins is Senior Online Editor for the CropLife Media Group at Meister Media Worldwide. See all author stories here.