Wilbur-Ellis’ New Stueve Facility Offers Speed, Precision

Wilbur-Ellis continues to turn to Stueve Construction to build its new facilities throughout the country. The latest project in Miller, SD, exceeded expectations on speed, precision and accuracy.

-

-

1 of 9

The exterior of the Wilbur-Ellis facility in Miller, SD, features multi-bin storage and enclosed truck receiving.

-

2 of 9

One of the key features in Wilbur-Ellis' new facility in Miller, SD, is the elevated control room.

-

3 of 9

A truck waits to receive a load in the receiving bay at Wilbur-Ellis' Miller, SD, facility.

-

4 of 9

Wilbur-Ellis says the new facility has sped up its input and output capabilities.

-

5 of 9

A fertilizer loader moves down the alleyway at Wilbur-Ellis' Miller, SD facility.

-

6 of 9

The alleyway at the Wilbur-Ellis facility in Miller, SD measures 264 x 36 feet.

-

7 of 9

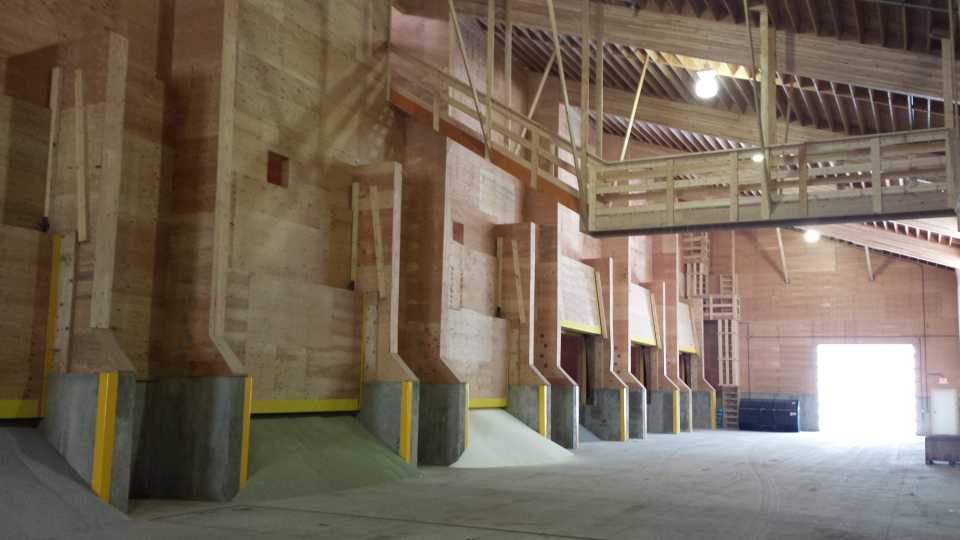

The new facility at Wilbur-Ellis in Miller, SD, features 11 bins with 13,825 ton capacity and 4 micro bins.

-

8 of 9

This conveyor belt moves dry fertilizer through the plant.

-

9 of 9

A view of the catwalk and conveyor system at Wilbur-Ellis' Miller, SD facility.

View all

What They Needed

Eric Jenks, Wilbur-Ellis

“Our goal was to put together a facility that would allow us to better serve our customer’s needs with speed, precision and accuracy. Our ever changing market demands and transportation concerns were drivers in our process,” said Eric Jenks, property development manager for Wilbur Ellis Co.’s Miller, SD, facility. “After many ‘brainstorming’ sessions with our Project Team, we developed a facility that could handle our dry and liquid fertilizer storage and blending needs for the future. We contacted Stueve Construction to put our ideas into a plan. Russ Buscher and Steve Anderson were instrumental in bringing our ideas to a building solution that not only met our expectations but exceeded them.”

Stueve has built numerous facilities for Wilbur-Ellis over the years and we know their people, said Jenks. “Key features that we really like are the elevated control room visibility of the loadout area and alley, catwalk/micro bin and tower stair system, in-floor heat system and enclosed truck receiving. Our new facility has without doubt, sped up our input and output capabilities and precision blending.”

Subscribe Today For

Hopkins is Senior Online Editor for the CropLife Media Group at Meister Media Worldwide. See all author stories here.